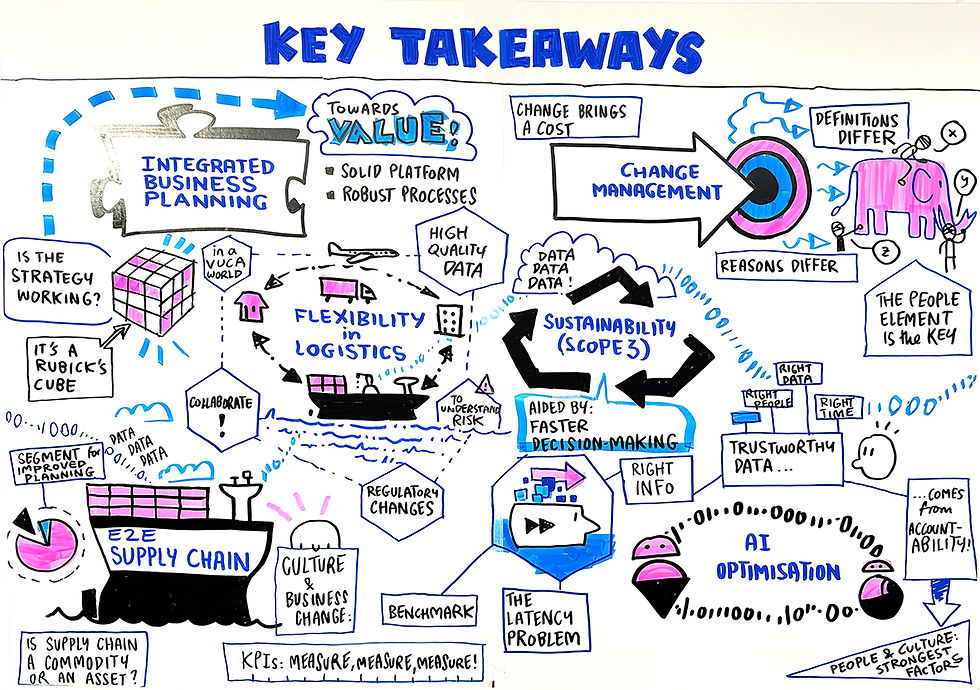

We covered so many of the conundrums and areas for improvement at the March Intent Meeting. As always, the Intent format is a hugely effective way to hear what others are doing and thinking, what's working and what perhaps isn't. There's no substitute for being there in person, and discussions are always open and honest because we operate under the Chatham House rule. Here's a brief rundown of our discussion leaders' summaries and conclusions.

Dave Food, Board - advancing towards IBP

Strategy - are we doing what we say we’re going to do? Aligning all of the plans around change is a challenge.

Making sure the plan is not only feasible but profitable. Were you able to drive wards understanding the trade off. Not just volume times value - but volume time profit, volume times revenue, cost - in order to play out the decisions.

Portfolio - are you managing your products? The unknown unknowns of the future that are part of the strategy but don’t have yet. Pulling it all together is difficult.

Conclusion

Make sure you have a good process in place with a flexible platform to drive it through to deliver business value consistently

Andrew Jackson-Proes, Visku: how to manage supply chain in a volatile world.

Access to high quality data is crucial for planning and understanding where there is a blip - where the risks are.

Strong collaboration needed to unlock the solos with customers

Challenge for retail customers - seeing resources being withdrawn - so desire to talk to the teams more to get a picture of demand.

Collaboration with your wider ecosystem - everyone has a role to play to reduce risk.

Geopolitics and the implications for supply chain planning. How supply chain leaders need to become more ever more informed in this topic because events can develop and change quickly.

Need better information to make decisions: depending on the industry you're serving regulatory changes and interpretation causing uncertainty and unpredictability

Some have been in a good place to capitalise after COVID - there are buying opportunities to take advantage of the one-off growth whilst maintaining supply chain efficiency

Seasonality and demand planning challenges and in particular the lack of storage flexibility

Improving product and customer segmentation

Clive Geldard, EFESO: Faster decision making: process, data and behaviours to drive results

Latency is a real issue. Delays and procrastination in decision making is a cost to the business for example in terms of response to market opportunities or supply chain disruptions.

The discussions highlighted challenges in putting the right information, at the right moment, with the right quality/ granularity to take the necessary decisions in a timely manner.

Highly fragmented data that is scattered across multiple systems is a common problem. Limited connectivity between systems requires manual processes with additional time spent extracting and manipulating data to get visibility of meaningful insights on which to take decisions.

There can be a lack of understanding on how decisions will be taken, and by whom. Lack of accountability or confusion around information and workflow inhibits speed. It can result in people coming to decision meetings without the right information or scenarios evaluation on which to act.

Building confidence in the data and having strong data governance foundations is seen as critical, as is meeting effectiveness. For example, using exception management and R-A-G dashboards with relevant insights to focus discussion, decision record and follow up.

Potential Solutions to improve speed improve the speed of decision making and reduce latency.

Very few are measuring how long it takes to take key decisions – what does good look like? Benchmark key processes e.g. time to market/ NPD, getting products and decisions through stage gates

Trust and empowerment of teams: calling out the opacity around responsibility for decisions. SIPOC (supplier, input, process, output, customer) - are we clear in the workflow and RACI?

Business and operating strategies – what decisions and information is required to evaluate trade-offs and align strategies.

Culture and people: adopt a continuous improvement mindset. Call-out latency and delay as a loss/ opportunity. Learn from experience. What can be done differently next time to be more agile and eliminate latency.

Nathan Varma, Beacon: end to end supply chain

Getting the right info to the right people at the right time is the key challenge most face. For most, data is in different systems - not always disseminated. If we can do more to fix a part of the puzzle - ie get the information to some of the right people at the right time it will enable you to make faster decisions, to take advantage of opportunities

Sustainability: a lot of the challenges are around measuring it consistently in a creditable methodology and that does not take too long. You’re better off outsourcing it than taking that on internally.

Ahmed El-Alfy, Zencargo: change management

We all share the same issue that change management always has a cost to it. Be it resource, time. Setting expectations of what drives change - it is different in each organisation. Different functions will have a different view of change. We have to align on expectations of change.

What makes us want to change? Are those people involved in the opening stages - if not they are resistant. Always a human element to change.

Project managers - get them involved to steer change - but they need to be bought into ensuring the change is actually being effective.

Martin Croucher, The Logic Factory: planning strategies for supply chain excellence

More, but by no means all, companies view the supply chain as a critical way of overperforming in their market, sometimes reflected on whether there is a Supply Chain Director role at Board level.

There is a recognition that there is always room for improvement in the supply chain with a lot of reliance on human expertise to overcome limitations of spreadsheets and fragmented planning solutions. Closing the gaps with a full virtual twin of integrated digital supply chain planning remains an aspiration - an area of expertise that we can continue to address.

Data: lots of information available but not fully harnessed into supporting business decisions, data security and the challenges of managing regional regulations was a big topic

Getting the right approach to business change and developing culture.

Supply chain evolution, from using KPIs well, recognising what a good plan looks like and moving from spreadsheets, live decision support and optimisation

Use of AI is a popular area of consideration and discussion - how could this fit in with future planning advances

Comments